Resources

Introduction

Plastics play a critical role in prosthetic manufacturing by

providing the ideal balance of durability, flexibility, and comfort for

amputees. For decades, prosthetists relied on t

…

The Vital Role of Marine Grade Plastics

Beyond the Marina:Marine grade plastics play an indispensable role in the

marine industry due to their exceptional durability, resistance to harsh marine

environments, and versatility. These special

…

The Versatile Power of Seaboard HDPE Sheets

Introduction

High-density polyethylene (HDPE) is an incredibly versatile plastic known for its durability, chemical resistance, and longevity in harsh outdoor environments. This makes it an ideal ma

…

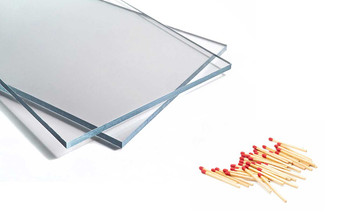

POLYCARBONATE VS ACRYLIC: CHOOSING THE PERFECT PLASTIC

Introduction

Polycarbonate and acrylic are two of the most versatile and

widely used plastics across a variety of industries. Both offer useful

properties like strength, clarity, and weather res

…

A complete guide to Aluminum Composite Panels

In addition to their structural benefits, composite panels offer an eco-friendly alternative to traditional building materials, reducing the carbon footprint of construction projects. Their flexibi

…

Design & Display

ABOUT DESIGN & DISPLAY PLASTICSPlastics are becoming an increasingly popular choice for construction and maintenance projects. Not only are they cost-effective, they are also much more durable tha

…

Room Dividers & Single Panel Partitions

Warehouse Partitions and Office DividersTotal Plastics has rolled out three new products to help support businesses in their continuing effort to rethink safety and create an environment that is safer

…

DIY Drum Enclosure

DIY Drum EnclosureTotal Plastics receives a lot of requests from individuals

building a custom drum set enclosure or drum shield. Typically, the enclosure

is for a church’s worship team who is looki

…

Medical Grade

ABOUT MEDICAL GRADE PLASTICSPlastics play an essential role in the life sciences and healthcare industries due to their ability to meet various demands of these sectors. Orthopedic manufacturers, for

…

FAQ Acrylic & Clear Plastic

Is acrylic more expensive than polycarbonate?No, pricing on standard stock acrylic is typically 25% less

expensive than the same sized piece of polycarbonate. Pricing can fluctuate

based on avail

…

Understanding Flame Retardant Polycarbonate

One of the more common questions customers ask is in regards

to the flame rating or flammability of polycarbonate. Often times, the

individual is trying align a building code with the material’s fla

…

FAQ High Performance Engineering Plastics

What’s the difference between Nylon 6, Nylon 66 and Nylon 101? Nylon 6 is cast nylon. Nylon 6/6 is extruded. Nylon 101 is a brand-name of Nylon 6/6 (sometimes typed Nylon 66). Nylon 6/6 has the best r

…